Process Specification:

Pressure Cure Applications:

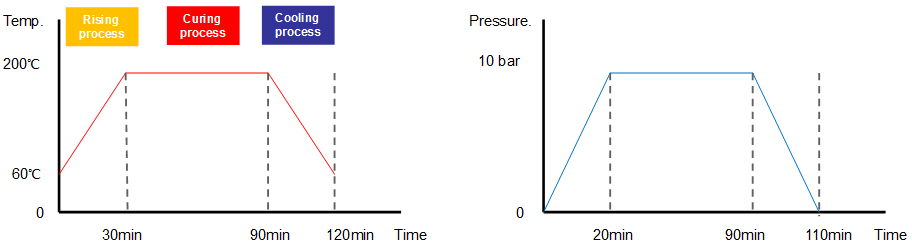

Representative Pressure/Temp Profiles (User Configurable)

We know you hate sales guys & you don't have a lot of time. We can do a consult over Webex and let you ask questions without having to listen to a sales pitch.

We welcome you to visit any of our facilities - USA, Asia, Europe to get a closer look at our products and have all of your questions answered.

4 Vreeland Road,

Florham Park, NJ 07932, USA

+1-973-377-6800

+1-973-377-3862

help@hellerindustries.com

Heller offices span the globe to facilitate the needs of our customers. Find representative

Join our mailing list to get future updates on new technologies!